Research labs worldwide have developed drones, satellites, improved telescopes, and other vital devices with high-quality lenses, but these are bulky, costly, and heavy. When drones that fly in the sky are involved, every gram that lenses weigh counts and can weigh them down.

Ordinary household items such as smartphones, binoculars, or even virtual-reality headsets also use high-quality lenses, but they must be lightweight and inexpensive.

Flat lenses are on the verge of commercialization for diverse applications. As such, the proper characterization of

these lenses is critically essential. Now, such technology will become available – cheap, lightweight, flat lenses around a thousandth of the thickness of a human hair – making their move the research labs to shops and homes.

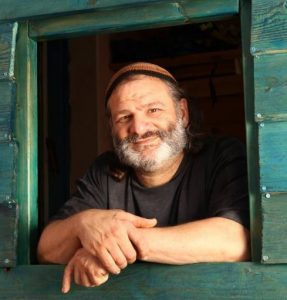

Several kinds of flat-lens technologies are available, but the challenge is to know which version is best suited for the specific application for which it was designed. This problem has been solved by Prof. Uriel Levy, director of the Hebrew University of Jerusalem (HUJI)’s Center for Nanoscience and Nanotechnology, together with postdoctoral student Dr. Jacob Engelberg.

They established a standard method to compare flat-lens technologies and designs and published their findings in the leading journal Nature Photonics under the title “Standardizing flat lens characterization.”

“The field of flat lens research brings innovative nanophotonic design concepts to the world of macro-optics. However, when evaluating the performance of these lenses, a lack of consistency prevents proper comparison of competing technologies,” they wrote in their study. “This problem can be solved by using methods developed in the industry for conventional lenses.”

The new flat lenses are advantageous compared to conventional lenses; with the ordinary types, the “stronger” the lens (the higher the prescription), the greater the curvature. In addition, the diameter of the lends, the thicker the lens. This causes problems for products such as consumer electronics, cellphones, VR headsets, and drones that should be as light as possible.

The new flat lenses are incredibly thin, and as the name suggests – they are flat rather than curved. However, there are different flat lenses designs and technologies on the market, and there are few guidelines as to which lens would be most appropriate for a given need.

In addition, manufacturers’ claims of success have been difficult to assess because there is no universally accepted method for comparing these lenses. With a simple way of production based on those used to create silicon chips, these new lenses will be extremely cheap and readily available.

Engelberg and Levy stepped in to create a proper method of comparison. “Adopting the standardized characterization methods that we’ve proposed will help this field progress,” Engelberg and Levy concluded.

The shortcode is missing a valid Donation Form ID attribute.