In a groundbreaking development with deep spiritual resonance, the Israeli milling company Shtibel has announced plans to produce semolina specifically kosher and pure for the Temple offerings—including the minchah (meal offerings) and the shtei halechem (Two Loaves) offering brought on the Festival of Shavuot.

Hebrew-language Makor Rishon reported that this marks the first time in millennia that a commercial company in the Land of Israel will manufacture flour in accordance with the strict halachic (Jewish legal) requirements for use in the Temple.

The semolina, made from new Israeli wheat, will be produced in a dry-milling process that ensures it does not become ritually impure—a necessary condition for offerings brought to the altar in the Beit HaMikdash (Holy Temple). The first shelf-ready products are expected to become available by Sivan 5786 (June 2026).

“And if thou bring a meal offering of firstfruits unto the Lord, thou shalt bring for the meal offering of thy firstfruits green ears of corn parched with fire, bruised corn of the fresh ear”

—Leviticus 2:14

“Ye shall bring out of your habitations two wave loaves of two tenth deals: they shall be of fine flour; they shall be baked with leaven; they are the firstfruits unto the Lord”

—Leviticus 23:17

The effort was initiated by Tzvia Svir, a resident of Kfar Zeitim in the Lower Galilee, who has spent years researching the precise halachic and technical requirements for preparing the Temple meal offerings. While most people became aware of the shtei halechem during its symbolic reenactment on Shavuot at the Temple Mount, Svir has been engaged in this niche field for decades.

Recognizing that Temple offerings require semolina ground from dry, unwetted wheat (as any contact with moisture makes it susceptible to ritual impurity), Svir worked for years to persuade Shtibel to create a special production line. The company agreed in 2019 to invest in dry-milling technology, but it was only in the past year that the process was finally tested.

In standard milling, wheat kernels are moistened to ease grinding. But for Temple use, this process is halachically disqualifying. Creating dry-milled semolina is much more complicated and results in significantly lower yields—typically only 3–5% of a wheat kernel can be used this way.

To produce even ten kilograms of semolina needed for a shtei halechem rehearsal, Svir had to supply half a ton of organic wheat grown in Israel. Through great effort and adherence to halachic constraints, she succeeded—and miraculously, 40 kilograms of pure semolina were produced. Svir’s lectures sparked widespread interest, leading Shtibel to make a strategic decision: they will now manufacture this rare product annually.

The new product comes just in time as an attempt to bring the two loaves of bread for the Shavuoth wave offering nearly came to pass earlier this month, but was prevented by the Israeli police.

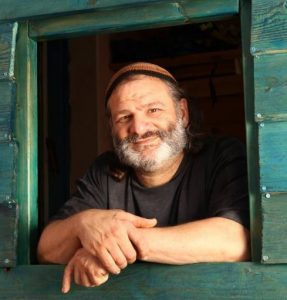

David “Fridi” Friedman, Shtibel’s head of R&D, is not religiously observant but is deeply immersed in the minutiae of Temple law. “The idea exists, it was tested, it needs refinement,” he explains. “The core principle is semolina made from a specific Israeli wheat, milled completely dry.”

When asked if there is real market demand, Friedman responds, “We don’t follow the market. We create it. This is something made 2,000 years ago. We’re trying to replicate it using modern tools. Many of our sources deal with this.”

Shtibel, a family-owned business for over 90 years, has always taken a long-term, values-driven approach. “We’re not a public corporation tied to quarterly reports. We think in generations. We cultivate unique Israeli wheat. Producing Temple-grade semolina is not profitable today—but we believe in vision,” Friedman states.

He notes that even in gentile cultures, locally grown, traditional crops hold deep symbolic value. “We should respect and reconnect with our own roots. Producing this semolina is about more than economics—it’s about belonging and destiny.”

The technical hurdles remain considerable. The wheat used must be of the new crop, harvested close to Shavuot, yet this type of wheat is often less suitable for baking because it hasn’t matured. Most commercial mills age wheat for three months, but for Temple use, the semolina must come from freshly harvested grain.

Further complicating matters, the wheat used must be carefully selected and processed separately to avoid disqualifying contact with moisture or impurity.

Despite the complexity, Shtibel believes they can meet the halachic and logistical requirements. According to Friedman, full-scale tests will continue through the coming winter, and by February 2026 they expect to complete development in time for the next wheat season.

Though Shtibel is not making any theological statements about the imminent rebuilding of the Temple, the company is proud to play a role in reviving a long-dormant aspect of Jewish life. Friedman compares his efforts to the family of Beit Garmu, who were responsible for baking the lechem hapanim (Showbread) in the Temple.

“We’re not trying to take their place,” he says, “but we’re happy to study and share the knowledge. Our sources describe in detail where the wheat was grown, how it was milled, and how the treasurer inspected it before use. It’s a privilege to be part of reviving that tradition.”

This initiative represents not only a technical milestone, but a spiritual one: the restoration of a chain broken for two millennia, tying modern Israeli agriculture and industry to the service of God in the land of the forefathers.

For many, it is more than a flour product—it’s a sign of redemption taking shape, one grain at a time.